Brief

Redesign a PET package within an industry to promote improved recycling

What is PET?

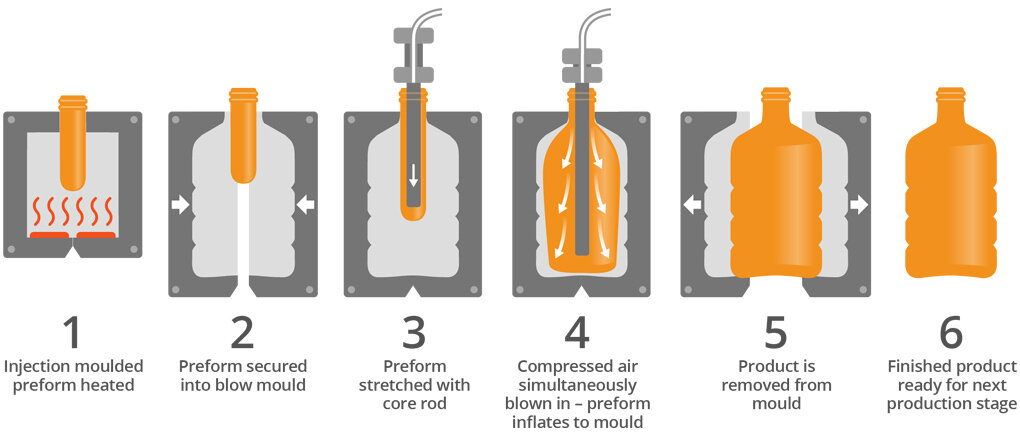

Synthesized around 70 years ago in the mid 1940s

PET is short for polyethylene terephthalate

The most recyclable plastic in the world. PET can be commercially recycled by thorough washing and re-melting, or by chemically breaking it down to its component materials to make new PET resin

Very energy efficient packaging

The high strength of PET in comparison to its light weight is a major key to its energy efficiency, allowing for more product to be delivered in less packaging and using less fuel for transport

More sustainable in comparison to glass and aluminum

Identifiable with a 1 on the bottom

Cosmetic PET

Excellent resistance to alcohols, aliphatic hydrocarbons, oils, greases and diluted acids

Wide range from semi-rigid to rigid for squeezing

Impact resistant and shatterproof

Resin can withstand humidity and keeps contents from drying out

Moldable into different shapes depending on brand identity

Can be fitted with pumps or finger sprayers

Stakeholders

Consumers

Waste Management

Engineers/Fabricators

Store Owners

There’s a huge drop-off in the amount of recycling that occurs when you move away from the kitchen.” According to a survey done by Unilever (which owns brands like Dove, Simple Skincare, and Nexxus), over half of Americans know that personal care products are recyclable but only 34 percent take the extra step to put them in the bin

According to Stephen Clarke, Head of Communications at Terracycle Europe,"120 billion units of packaging are produced every year by the global cosmetics industry"

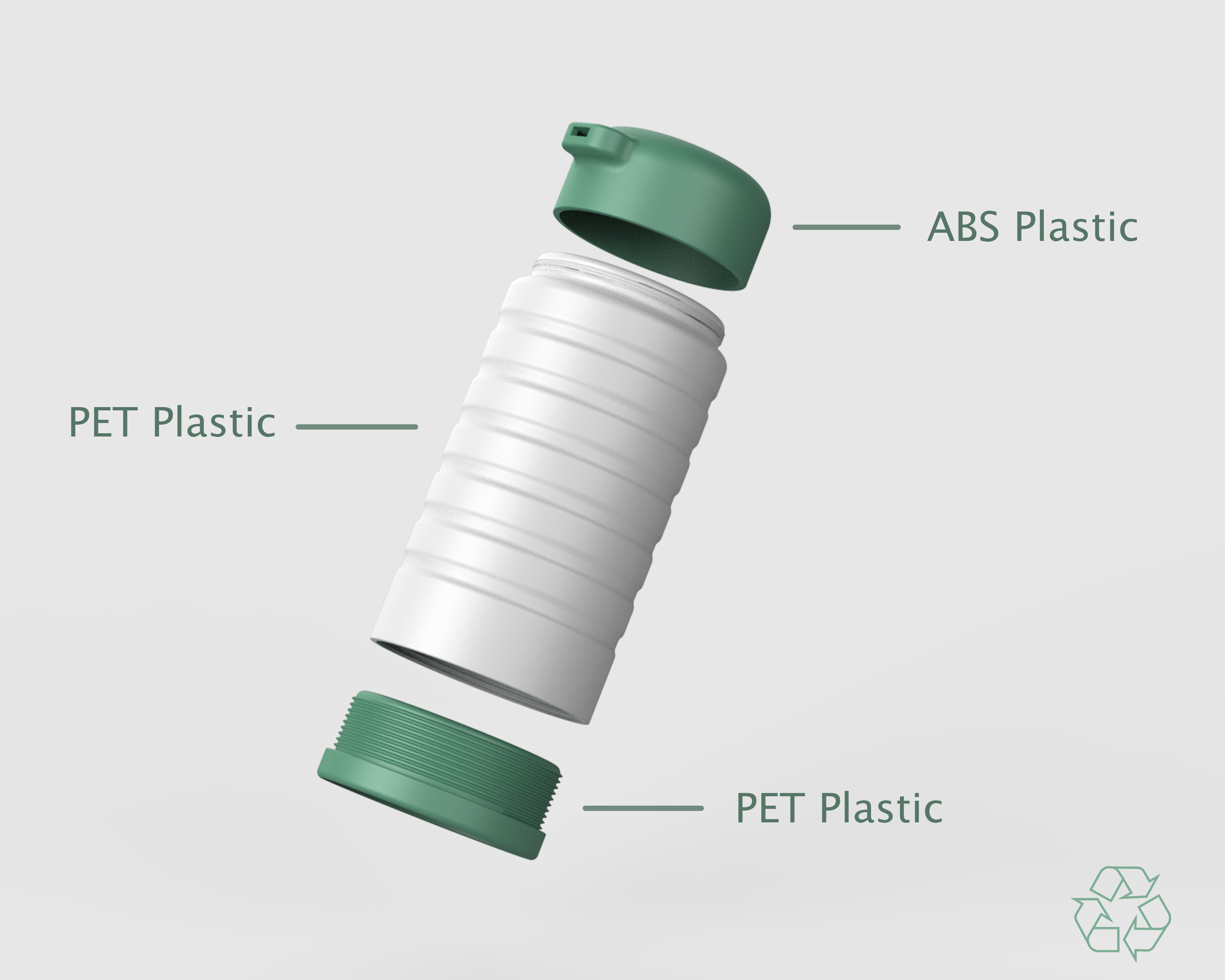

Certain parts of a recyclable product might not be recyclable, such as the pumps and droppers on top of bottles. Parts made of multiple materials are difficult to recycle; pumps might have something inside of them like a metal spring, and droppers can be a combination of glass, plastic, and that rubber squeezy thing.

PET can be recovered and recycled again and again by thorough washing and remelting for use in new PET products, or by chemically breaking down the PET into its constituent raw materials, which are then purified and converted into new PET.

Pump Bottles

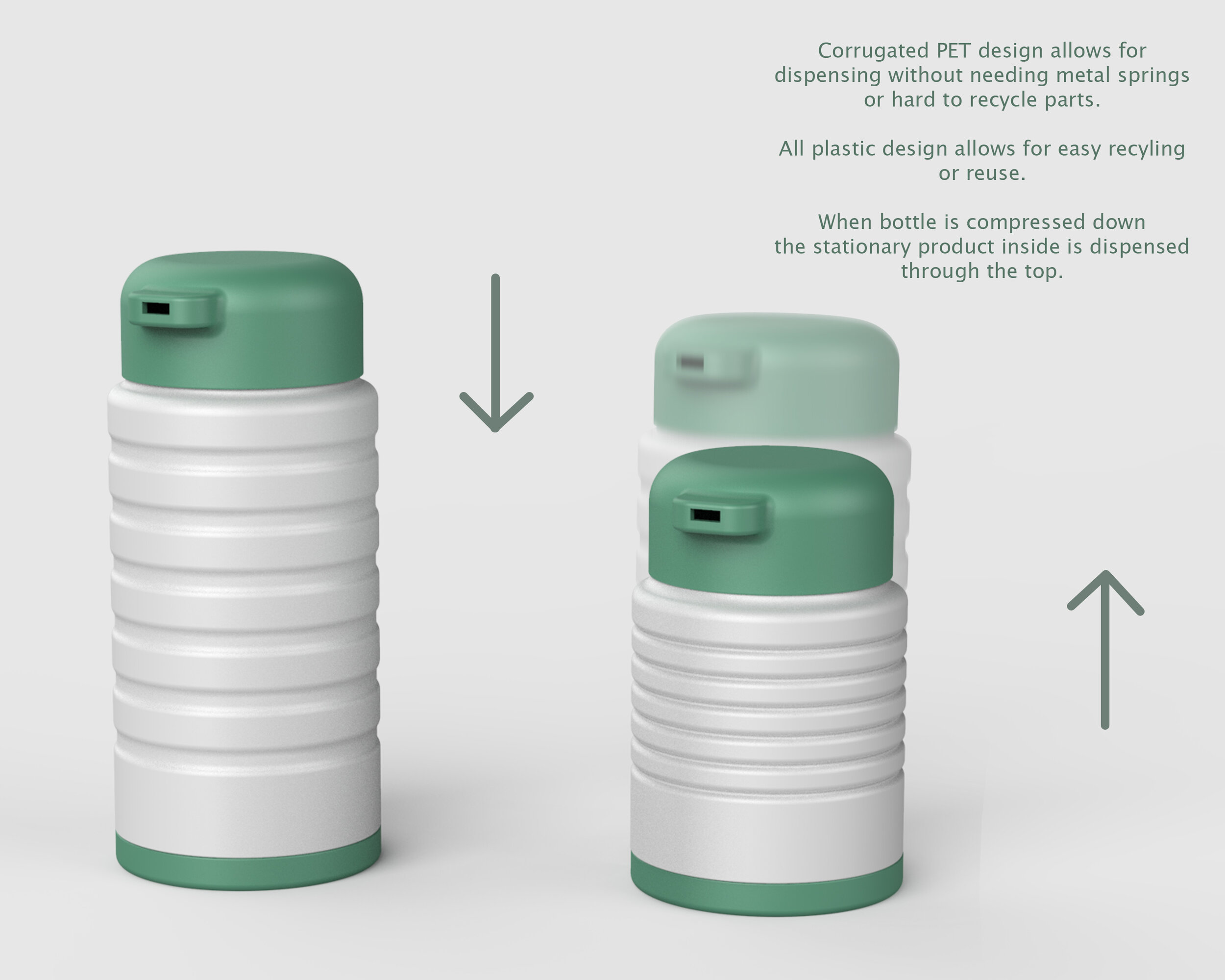

When analyzing PET packaging with the cosmetic industry one that really stood out was the pump bottles. While commonly used, they are difficult to recycle do to the multiple materials used. They often contain metal, plastic, and glass which is not able to be recycled together as well as wasting product because the straws cannot pick up all the product inside.

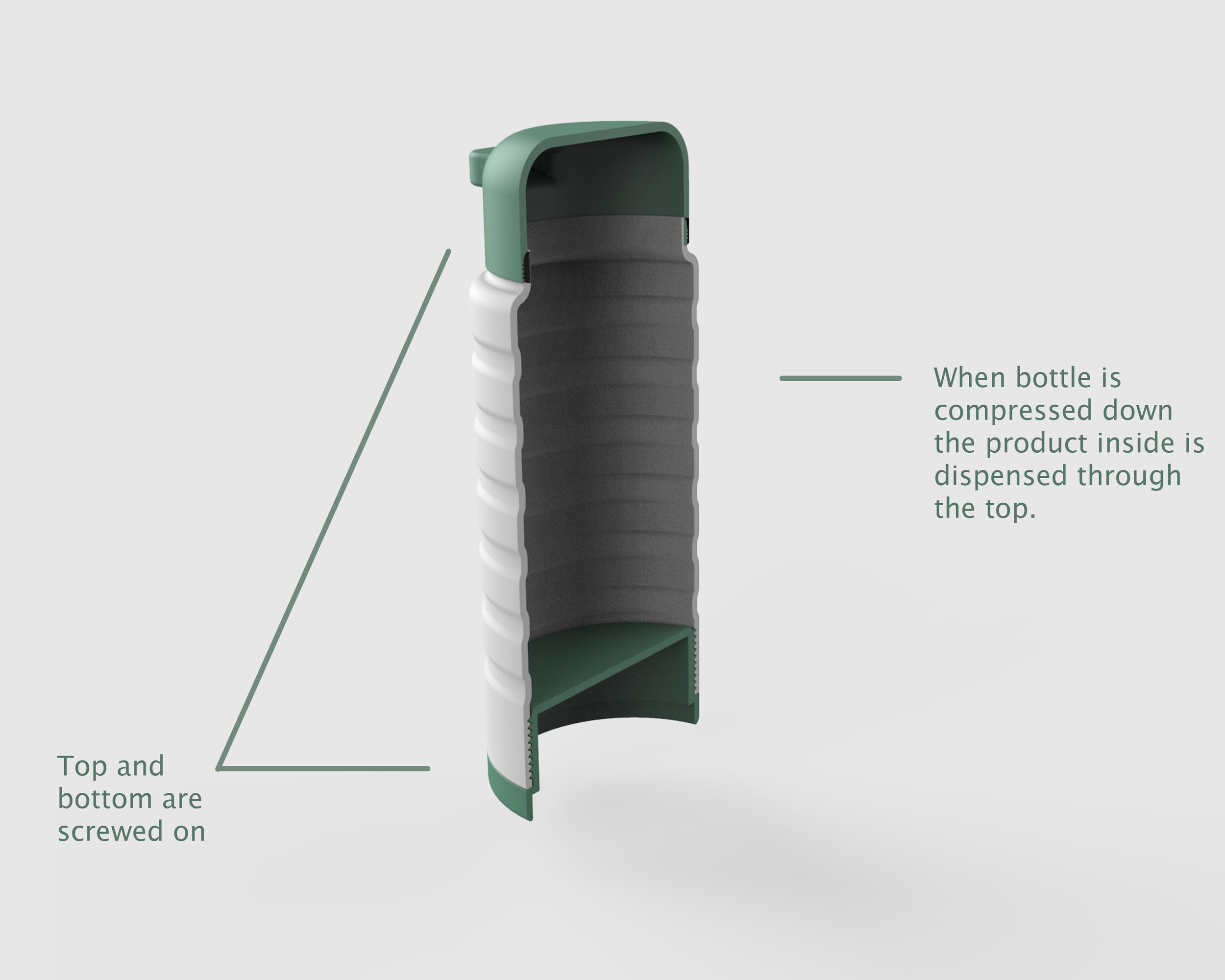

Similar to the airless pump that is already on the market, I wanted to create a pump that did not need to use any sort of straw attachment. The downside to the airless pump is that it still uses a metal spring on the top pump which still makes it difficult to recycle.

Idea 1

Disk is attached to rod in the middle

Use finger to slide the disk down to get product out to bottom hole

CON - In order to have sider there would have to be an opening and product would come out or go bad.

Idea 2

Push top down to get product out from bottom hole

CON - Cant push top all the way down to get all the product out

Too simple

Final Idea